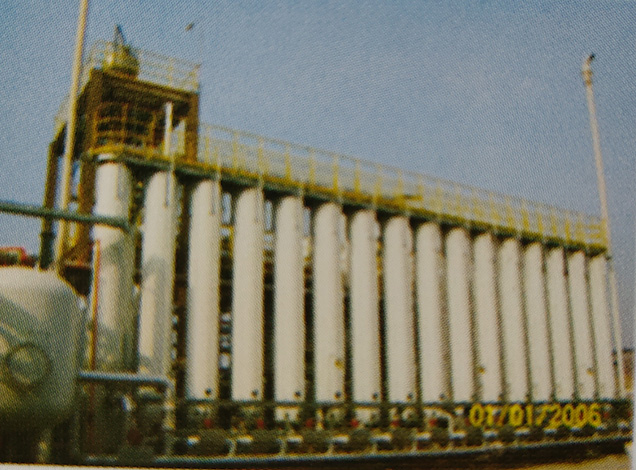

H2 palnt

-

Hydrogen generation plant by water electrolysis

Hydrogen generation plant by water electrolysis is to decompose water into one share hydrogen and 1/2 share oxygen under the action of DC power, it strictly follows Faradays law

The hydrogen generation equipment developed based on this technology mainly includes:

* Electrolyser: the generator of hydrogen and oxygen

* Auxiliary equipment frame: gas-liquid separation system

* Rectifying transformer + Rectifier: DC power supply unit

* PLC control panel: the automatic control unit

* Feed water & lye making system: include lye tank, feed water tank, lye making pump, this unit is used for making electrolyte solution and feed water storing.

The total system is automatically controlled, the hydrogen, oxygen are supplied under the

required pressure.

Hydrogen generation equipment by water electrolysis is very suitable for site production of hydrogen gas because it only needs water and electricity as materials, and used widely in many industrial fields, include metallurgical, chemical, float glass, electrical power, oil & grease and nuclear industry, aerospace and military fields, etc.

The hydrogen capacity of THE products is from 0.1Nm3/h to 1000Nm3/h, the work pressure can reach to 50barg without compressor, it is the highest in the world. The products are divided into 7series:

FDQ5: 2~8Nm3/h

FDQ10: 8~20Nm3/h

FDQ20: 20~40Nm3/h

FDQ60: 40~60Nm3/h

FDQ100: 60~150Nm3/h

FDQ400: 150~400Nm3/h

FDQ800: 400~1000Nm3/h

And:

Mini-type plant from 0.1 to 2Nm3/h

Special designed plant for power plant

Cabinet type plant

Containerized plant

Methanol cracking produces hydrogen

Under the action of certain pressure and temperature and special catalyst, the mixed steam of methanol and water is transformed into -75% H2 and ~24% CO2 and a few conversion gas with CO&CH4 (unreacted water and methanol gas, through automatic program controlling return raw material liquid tank to recycled use. After heat transfer, condensation CO、CH4、CO2 purification and then pass disposable the converted gas is separated and removed by pressure swing adsorption (PSA) device.

Technical characteristics

● Materials are easy to attained

● Low energy consumption, low consumption, low cost

● High automation, high hydrogen purity, high safety performance

● No pollution, no starting, no parking loss

● High intensive, exquisite appearance, strong adaptability to the construction site.

(Size less than 600 Nm3/h Pry mounted 600 Nm3/h above on site installing)

Technical index

Raw materials consumption:0.5-0.65kg/Nm3

pressure: :0.8-2.5Mpa

Hydrogen purity: industrial hydrogen, pure hydrogen, high purity hydrogen (GB/T7445-1995)

Production of hydrogen from natural gas

At a certain temperature, pressure and catalyst, alkane and water vapor in natural gas react chemically to obtain the conversion gas containing H2、CO、CO2、N2、CH4. The carbon monoxide in the converted gas reacts further with water vapor to form H2 and CO2.. After heat transfer, condensation and steam separation, the conversion gas was separated by pressure swing adsorption (PSA) through the adsorption tower containing a variety of specific adsorbents in order to extract the product hydrogen.

Technical characteristics

● Gas is both feed stock and fuel gas

● Energy consumption is low, consumption is low, hydrogen cost is low;

● It is more suitable for large-scale hydrogen production (scale >1000/ Nm3/h plant) than methanol split hydrogen production

● Compared with coal gas production, covers a small area, no pollution, no waste residue and good environmental protection of the performance.

Technical index

Unit consumption :0.47-0.55 Nm3/Nm3 (within fuel gas)

Pressure: :1.0-2.5Mpa

Electricity consumption: less than 0.3 Kwh/m3

Hydrogen purity: industrial hydrogen, pure hydrogen, high purity hydrogen (GB/T7445-1995)